Cardboard balers for sale

Energy-Efficient Cardboard Baling Machines That Reduce Waste & Save Money

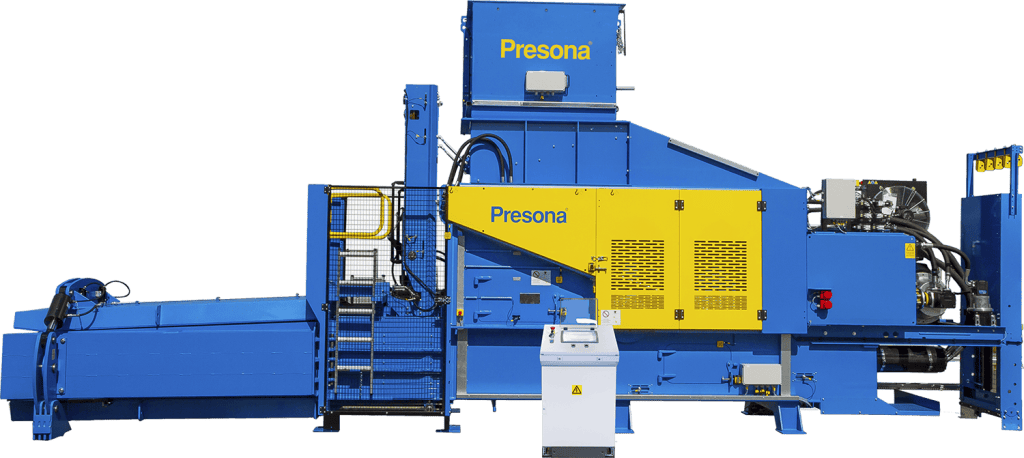

Presona is a leading manufacturer of industrial cardboard balers, compactors, and baling presses for recycling operations of all sizes. Our Swedish-engineered cardboard baling machines are designed to handle Old Corrugated Cardboard (OCC) and various other materials with exceptional efficiency and durability.

Why Choose Presona Cardboard Balers?

- Low Total Cost of Ownership: Actually lower than most other balers.

- Prepress Technology: Creates high density bales, reducing transportation costs

- Energy Efficiency: Save up to 30% on electricity compared to most other balers

- Low Operating Costs: Durable machines that use 10% less baling wire.

- Versatile Operation: Effectively bale cardboard, paper, plastic, RDF and more

- Swedish Quality: Exceptional durability ensures years of reliable operation

- Automatic Bale Tying: Increases operational efficiency and reduces labor costs

- Easy Maintenance: Quick access design minimizes downtime and service costs

The Prepress technology saves energy

Using our prepress system, the baler will no longer cut off excess material. Instead it will rely on an initial pre-compression step to achieve the best bales.

- The prepress and main press are in the starting position. Material fills the main press chamber and hopper.

- The prepress descends, compressing the material with downward force, ensuring the chamber is fully filled.

- The main horizontal ram compresses the material using maximum force. The press chamber is closed = no knives required to cut off material. While steps 2 and 3 are taking place, material continues to fill the hopper.

- Compression continues until the pre-set bale length is reached. Bale strapping begins.

- The prepress opens and material from the hopper fills the chamber again. A new press cycle starts.

Our Cardboard Baler Range

Whether you’re a small business or a large recycling facility, we have the perfect cardboard baler solution to meet your specific needs. Keep in mind: They can bale many other materials, not only cardboard!

| Model | Capacity/hour* | Materials |

|---|---|---|

| LP 50 | 13 tonnes | Cardboard, plastic, paper etc. |

| LP 60 | 18 tonnes | Cardboard, plastic, paper etc. |

| LP 85 | 21 tonnes | Cardboard, plastic, paper etc. |

| LP 110 | 29 tonnes | Cardboard, plastic, paper etc. |

| MP 270 MH | 45 tonnes | Cardboard, plastic, paper etc. |

*Material weighing 50 kg/m3 before baling.

Why Presona? Trusted by Businesses Worldwide

- Decades of Expertise – Swedish-engineered balers for the toughest industrial demands

- Lower Costs, Higher Efficiency – Reduce energy bills and waste management expenses

- Built for the Future – Sustainable baling solutions that help businesses go green